Click the crane POW to highlight it, and select Actions  Set Dispatch Mode

Set Dispatch Mode  Trucks.

Trucks.

This example describes an RTG vessel load of a single container per truck with Truck Control. The table summarizes the job steps, indicating who performs each step and the dispatch state of the work instruction (WI).

Job Steps for RTG Vessel Load (One Container) with Truck Control

|

Job Steps |

Who Can Perform |

WI Dispatch State |

|---|---|---|

|

1. Activate the vessel load queues, and select the Trucks dispatch mode for the crane POW. Equipment Control automatically assigns work to available trucks. |

dispatcher |

assigned |

|

2. In the VMT, log in and become available. Equipment Control sends a truck message with directions to the yard block and the equipment id of the assigned container. Proceed to the yard block and report arrival through the VMT. |

truck driver |

assigned |

|

3. In the VMT, log in, become available, and request a job list. Equipment Control sends a list of marked containers in the RTG zone. |

RTG operator |

assigned |

|

4. Select a job from the job list to dispatch it. Equipment Control sends a job message with the list of available trucks. |

RTG operator |

dispatched |

|

5. Enter a truck ID and SUBMIT in the VMT to record the move to the truck. Equipment Control updates the move to the truck position, and sends the truck a message with directions to the crane or berth. |

RTG operator |

in progress |

|

6. Proceed to the quay and report arrival at the quay through the VMT. |

truck driver |

in progress |

|

7. Log in to the Hatch Clerk vessel load program. When the truck arrives at the quay, and after the crane loads the container, enter the container ID and the actual vessel load position, and perform any required inspection. |

hatch clerk |

in progress |

|

8. Submit the vessel location and other inspection data. N4 sends a message to Equipment Control, and Equipment Control completes the move. |

hatch clerk |

completed |

To perform a vessel load of a single container from an RTG zone with Truck Control:

Click the crane POW to highlight it, and select Actions  Set Dispatch Mode

Set Dispatch Mode  Trucks.

Trucks.

Equipment Control assigns moves in active work queues to available trucks.

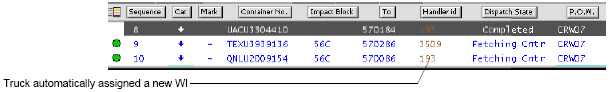

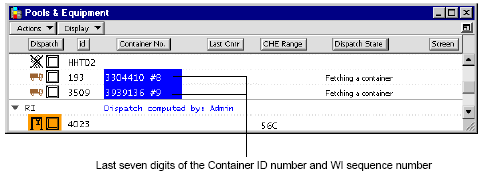

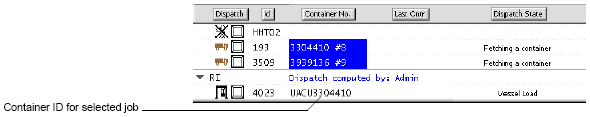

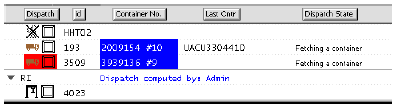

In the Pools & Equipment window, the Dispatch State for the truck is "Fetching a Container’. The last seven digits of the assigned container ID number and sequence number in the work queue appear in white text on a blue background.

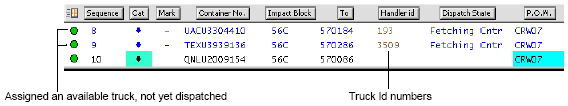

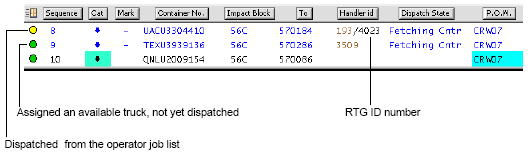

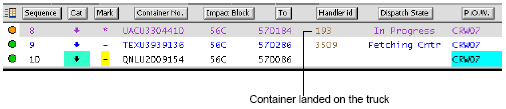

In the work queue, the work instructions are assigned (blue text with a green planning dot). The assigned truck ID numbers appear in the Handler id attribute, in brown text.

The Handler id attribute shows the current truck and CHE handling a container in a compact form. To monitor move stages, you can use separate CHE-fetch, CHE-Carry, and CHE-put attributes. For trucks, you can use the Truck No. attribute.

Equipment Control sends the truck a job message with the container ID number, and directions to the yard block and row.

Equipment Control sends a job list to the RTG covering the zone where the container is currently stacked. The job list shows the work instructions for that zone, and the truck ID for the truck assigned to the job.

Using the VMT, the RTG operator selects an item from the job list by entering the list number or container number in the second, open field, and presses SUBMIT.

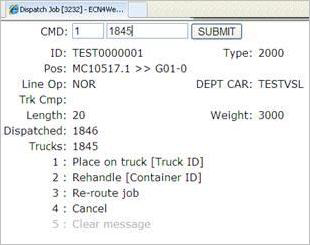

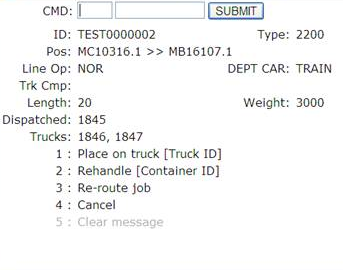

The VMT screen for the RTG operator shows the dispatched truck ID. If there are other trucks available for the dispatch, the truck ID(s) appear in the Trucks field, as in the image below.

In the Pools & Equipment window, a container appears on the RTG icon (under the Dispatch attribute), and the container ID appears in the Container No. attribute. The Dispatch State for the RTG is ‘Vessel Load’.

In the work queue, the Dispatch State is ‘Fetching Cntr’, both for the assigned and the dispatched container. The RTG ID is added to the Handler id attribute.

The RTG's VMT displays the job detail, with the container, the From and To positions, the dispatched truck number, as well as a list of ID numbers for other available trucks assigned to the quay crane POW.

If a yard shift (rehandle) is necessary, the operator can request a rehandle position by entering 2 into the CMD field, and the Container ID into the unmarked field to the right of the CMD field. For information about rehandling containers, see Monitor a rehandle (on page 1).

When the truck arrives, the RTG operator lands the container on it, then enters the truck ID number (Handler id), and presses SUBMIT. The job disappears from the job list, and Equipment Control immediately marks another instruction and sends it to the job list.

If a different truck arrives first, the RTG operator can land the container on it. Equipment Control automatically reassigns the original truck to a different move.

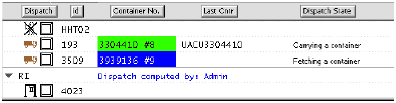

In the Pools & Equipment window the container number is now highlighted in green. The Dispatch State is ‘Carrying a container’.

In the work instruction the Dispatch State is ‘In Progress’. Both the Handler id and the Current Position display the truck ID number.

Equipment Control sends the truck a job message with the container ID, and the destination information of the job, such as the crane POW and vessel bay position.

For all rail loads (and discharges) releases 2.6 and above, ECN4 provides by default the Track-Pos/Spot (if this information has been recorded) as the container location in job stepping messages to ITV operators. If the Track-Pos/Spot information is not available, ECN4 provides the Railcar ID as the container location.

The job disappears from the RTG operator’s job list. Equipment Control marks another job automatically, and displays the updated job list on the VMT.

The truck takes the container to the assigned crane.

At the assigned crane and vessel bay, the hatch clerk is logged in to the Hatch Clerk program, and has entered the vessel visit ID and the crane ID.

When the crane loads the container, the hatch clerk enters the container ID, identifies the operation as a Load, and enters the actual vessel location where the container lands. When the hatch clerk submits the location, N4 sends a message to Equipment Control, and Equipment Control completes the move.

In the Pools & Equipment window, the container ID number appears in the Last Cntr attribute. The container disappears from the truck.

Equipment Control completes the work instruction and immediately assigns the next move in the queue to the truck. The completed work instruction appears in gray at the top of the work queue.